Worktable disc dimension: Φ250mm/Φ420mm/ Φ630mm/Φ800mm

Max rotational diameter: Φ400mm/Φ540mm/Φ800mm/Φ1050mm

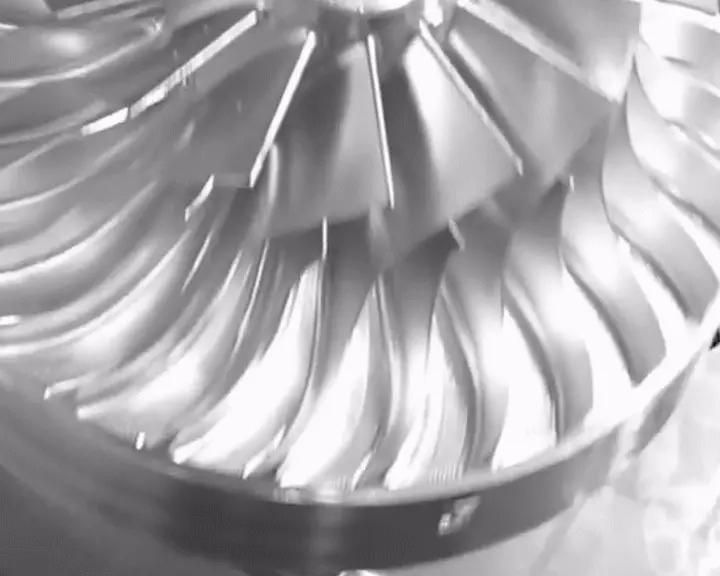

FLLS 5-axis cnc machining center is a 5-axis 5-simultaneous working method. The linearity of any 5 coordinate axes of X, Y, Z, A, C can be processed simultaneously. The 5-axis CNC machining center is a CNC machine tools with high technology, high content and high precision are specially used for processing complex curved surfaces. At the same time, they are the only way to solve the processing of impellers, blades, marine propellers, heavy-duty generator rotors, steam turbine rotors, and large diesel engine crankshafts.

Advantage:

Best in class components:

1. Spindle: Taiwan Royal/Cells/Germany INNA

2. Control system: Fanuc/Heidenhain/Siemens/Syntec/Lynuc (Optional)

3. Screw rail: Taiwan HIWIN/PMI

4. Bearing: FAG/NSK

5. Machine tool castings: HT300, which enables the machine tool to obtain high rigidity and stable precision;

6. Cradle Rotary Table: Choose the well-known brand Taiwan Parkson Cradle Rotary Table.

Structure:

1. Double Y-axis and double-drive structure: high precision and good stability, especially the verticality accuracy under heavy cutting;

2. Axis accuracy: the accuracy of the inclined axis reaches 25", and the accuracy of the rotating axis reaches 10" (the accuracy of the inclined axis and the rotating axis directly affects the spatial dimension accuracy of the processed parts);

3. High precision: positioning <4μm, repeat positioning <3μm (full stroke VDI standard);

4. Spindle taper: BT40 12000rpm standard (optional);

5. Tool magazine: ATC 24 units tools (Optional);

| Model | FLLS-F0 | FLLS-F1 | FLLS-F2 | FLLS-F3 |

| Worktable | ||||

| Worktable disc dimension | Φ250mm | Φ420mm | Φ630mm | Φ800mm |

| Max rotational diameter | Φ400mm | Φ540mm | Φ900mm | Φ1050mm |

| A axis rotation range | +20°/-120° | +20°/-120° | +20°/-120° | +20°/-120° |

| C axis rotation range | +360°/-360° | +360°/-360° | +360°/-360° | +360°/-360° |

| A,C axis positioning accuracy | 45/15sec | 45/15sec | 10/10sec | 45/15sec |

| A,C axis repeat positioning accuracy | 8/6sec | 8/6sec | 4/4sec | 8/6sec |

| Max load (level) | 50kg | 200kg | 850kg | 1000kg |

| Max load (tilt) | 50Kg | 150Kg | 850Kg | 500kg |

| XYZ | ||||

| X/Y/Z axis max travel | 400/400/350mm | 500/500/400mm | 800/800/600mm | 1100/1100/650mm |

| Distance from spindle end face to table | 130-480mm | 130-530mm | 130-730mm | 130-780mm |

| Spindle | ||||

| Spindle taper | BT40 | BT40 | BT40 | BT40 |

| Max speed of spindle (standard) | 12000rpm | 12000rpm | 12000rpm | 12000rpm |

| Spindle drive mode (standard) | direct-connection 12000 | direct-connection 12000 | direct-connection 12000 | direct-connection 12000 |

| Feed | ||||

| Feed rate | 10000mm/min | 10000mm/min | 10000mm/min | 10000mm/min |

| Fast moving speed | 36/36/36m/min | 36/36/36m/min | 36/36/36m/min | 36/36/36m/min |

| Ball screw specifications | 4016 | 4016 | 4016 | 4016 |

| positioning accuracy | ±0.005/300mm | ±0.005/300mm | ±0.005/300mm | ±0.005/300mm |

| Repeated positioning accuracy | ±0.003/300mm | ±0.003/300mm | ±0.003/300mm | ±0.003/300mm |

| Tool magazine (optional) | ||||

| Tool magazine capacity | 20 | 24 | 24 | 24 |

| Tool diameter * length | 80X200mm | 80*200mm | 80*200mm | 80*200mm |

| Tool weight | 8kg | 8kg | 8kg | 8kg |

| Shank specification | BT40 | BT40 | BT40 | BT40 |

| Servo motor | ||||

| Spindle motor | 7.5/11kw | 11/15kw | 11/15kw | 11/15kw |

| X/Y/Z Axis motor | 2.0/2.0/3.0kw | 3.0/3.0/3.0kw | 3.0/3.0/3.0kw | 3.0/3.0/3.0kw |

| Cooling motor | 0.49kw | 0.49kw | 0.49kw | 0.49kw |

| General specification | ||||

| Air supply requirements | 8KG | 8KG | 8KG | 8KG |

| Power capacity | 20KVA | 30KVA | 50KVA | 60KVA |

| Dimensions (L * W * H) | 2.5*2.6*2.6m | 3*2.8*2.8m | 4.5*3.6*3.4m | 4.8*4.2*3.6m |

| Weight | 5T | 9T | 14T | 20T |

FLLS 5 axis cnc milling machine machining center is widely used in aerospace, information and communication, automobile mold, medical instruments, machinery manufacturing and parts processing and other industries.

FULALEISA Intelligent Equipment (Anhui) Co., LTD.

FULALEISA Intelligent Equipment (Jiangsu) Co., LTD.

"CNC Corporation" LLC(Belarus)

Email:[email protected]